Warehouse Management Suite (WMS): First Logiks Mobile and Web App

As we look ahead to 2024, the landscape of Warehouse Management Systems (WMS) is poised for transformative change, that Logiks is determined to keep up with.

In this dynamic environment, the Logiks Solutions Mobile Application emerges as a useful tool, redefining efficiency in warehouse operations of all sizes. Seamlessly integrated with SAP Business One, Logiks WMS streamlines the management of warehouse processes, eliminating the need for manual data entry on a PC. With core functionalities at your fingertips through various modules, Logiks WMS is set to assist in navigating and relieving the hardships of warehouse management.

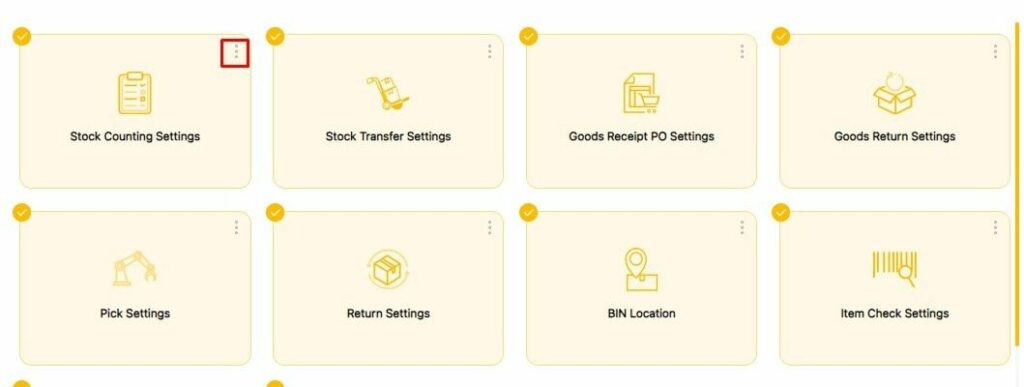

Key Modules of WMS App for Enhanced Efficiency

The app boasts a range of modules designed to optimize warehouse workflows:

- Stock Counting: Simplify stock counting with easy barcode scanning functionality.

- Stock Transfer: Facilitate stock transfers between locations with a few scans.

- Goods Receipt PO: Automate goods receipt processing based on purchase orders.

- Goods Return: Streamline the return process with efficient barcode scanning.

- Pick: Update pick lists and create delivery documents with partial scanning capabilities.

- Return: Manage sales returns with ease.

- Stock Goods Receipt: Record stock receipts accurately and quickly.

- Bin Location Check: Verify product availability by bin locations.

- Item Check: Access item master data with a simple scan.

What is Cloud-Based WMS?

Cloud-based WMS refers to a Warehouse Management System (WMS) software solution that leverages online technologies like virtualization and distributed computing. This allows users to access web-based services for inventory, order, and logistics management in a secure, easy, and reliable manner. Unlike traditional WMS systems, cloud WMS does not require local physical hardware or software, streamlining operations and reducing the need for on-site infrastructure.

How Does WMS Function in Correlation to the Cloud?

Cloud-based systems generally operate by granting an organization access to online computing resources, thereby reducing the need for substantial in-house capital investments.

This hosting model utilizes off-site infrastructure, including computers, storage devices, and other services hosted in the cloud, eliminating the dependence on local hardware, software, and dedicated IT personnel. This approach not only simplifies IT management but also offers scalability and flexibility to adapt to changing business needs.

WMS Features Include:

- QR-Code Functionality: Customize QR-code settings with a drag-and-drop interface, allowing for seamless scanning or manual data input.

- UDFs (User Defined Fields): Show or hide selected row and header UDFs from SAP Business One for a more tailored user experience.

- Auto-Generation of Batch & Serial Numbers: Define logic for automatic numbering, ensuring precision and eliminating manual efforts.

- Batch Segmentation: Manually determine the number of items per batch for greater flexibility and control.

- Help Button: Access help articles with just a click, providing immediate assistance.

- Backend Settings: Fetch and update backend settings responsible for a secure connection between the barcode scanner and your company’s Service Layer.

- Language: Adapt the application interface in English and German.

- Automatic Data Synchronization: Keep data consistent between the SAP Business One Database and the Logiks Solutions App with automatic synchronization at chosen time intervals.

- Printing Labels: Print item labels directly from the barcode scanner, handling serial and batch items across different transactional scenarios.

Configuring Templates on WMS App

In the e-commerce sector, where businesses often deal with a high volume of orders with varying requirements, automated templates come into handy.

You can streamline their picking, packing, and shipping processes, ensuring that orders are fulfilled accurately and promptly.

Another example is in the food and beverage industry, where storage and handling requirements can be quite specific. Templates allow for the customization of storage conditions for different products, ensuring compliance with safety standards and reducing the risk of spoilage.

Additionally, in the fast-paced retail environment, templates facilitate quick adjustments to inventory management practices during peak shopping seasons or promotional events.

The use of templates in these scenarios shows directly how they contribute to the scalability and cost-effectiveness of warehouse operations, making them an indispensable feature in modern WMS solutions.

To configure templates on a Warehouse Management Suite (WMS) remotely, there are a few key steps to go through:

Access the WMS: Log in to your WMS software from a remote location. This usually requires a secure internet connection and the appropriate login credentials.

Navigate to Template Management: Find the section of the WMS where templates are managed. This could be called “Template Configuration,” “Template Management,” or something similar.

Create or Select a Template: If you’re creating a new template, you’ll typically start by selecting “New Template” or a similar option. If you’re modifying an existing template, you’ll need to locate and select the template you want to configure.

Define Template Settings: Configure the settings for your template. This can include specifying which fields are included, setting default values, and defining rules for how data should be processed. The specific options available will depend on the capabilities of your WMS.

Save and Apply the Template: Once you’ve configured the template to your satisfaction, save your changes. You may then need to apply the template to the relevant areas of your warehouse operation, such as specific tasks or processes.

Test the Template: It’s important to test the template to ensure that it’s working as expected. This might involve running a few trial operations or conducting a full test in a controlled environment.

Deploy the Template: After testing, deploy the template for use in your warehouse operations. This may require notifying relevant personnel and providing any necessary training.

Monitor and Adjust: Finally, monitor the performance of the template and make adjustments as needed. This could involve tweaking settings or updating the template to accommodate changes in your operations.