Après avoir connu une croissance exponentielle, Tin Shack et Australian Boot Company, un distributeur canadien de premier plan de marques de chaussures telles que Blundstone et Glerups, ont reconnu la nécessité de moderniser leurs systèmes hérités. Tin Shack est le distributeur exclusif des bottes Blundstone pour le Canada, expédiant souvent des milliers de paires par jour. Ils ont recherché une solution ERP moderne pour améliorer leur flexibilité et leur scalabilité. L'entreprise a mis en œuvre SAP Business One avec l'aide de la société de mise en œuvre aclaros, visant à obtenir une meilleure visibilité opérationnelle.

However, despite the successful implementation of SAP Business One, Tin Shack faced inefficiencies in warehouse operations. With a high volume of orders, their existing warehouse picking solution lacked speed and flexibility. They sought a new warehouse solution that would fully integrate with their new SAP Business One ERP, was capable of reducing worker downtime and increasing the speed of warehouse operations.

Welcome to Logiks Solutions!

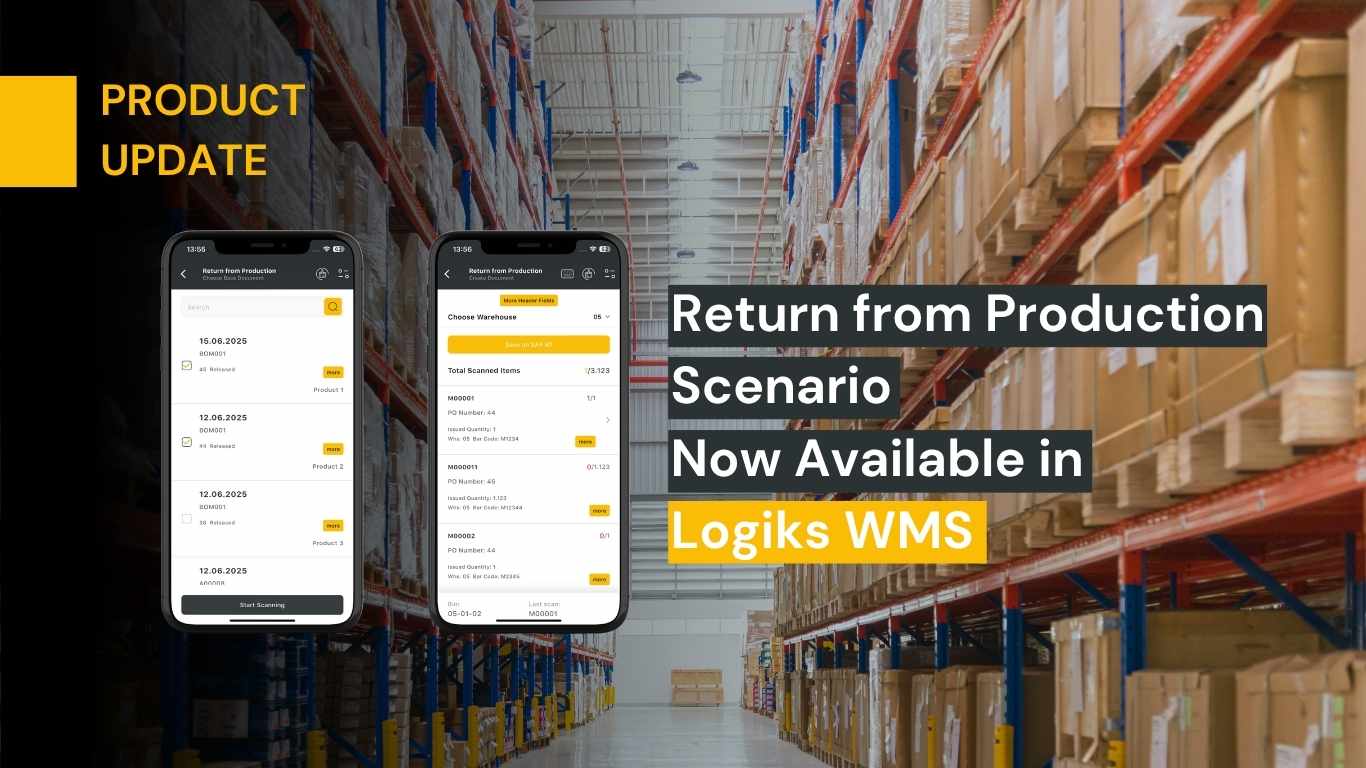

Tin Shack and Aclaros worked with Logiks to deploy their Warehouse Management Suite. The cloud-managed solution offered versatile

scanning capabilities, including support for barcodes, QR codes, and RFID codes. With mobile flexibility across iOS and Android devices,

Logiks aimed to streamline warehouse processes and enhance efficiency.

Smooth Implementation

The implementation of Logiks WMS solution took only 10 weeks, ensuring a rapid transition before Tin Shack’s busy season. Leveraging their existing SAP Business One infrastructure, the integration was seamless. Logiks provided comprehensive support throughout the process, including go-live assistance to ensure a smooth transition.

Speedy Results

The results of implementing Logiks’ Warehouse Management Suitewere transformative for Tin Shack:

- Improved Efficiency: Average pick time per unit reduced from 8 seconds to milliseconds, resulting in significant time savings.

- Labor Cost Reduction: By optimizing picking processes, Tin Shack achieved substantial labor cost savings, allowing for a 20% reduction in warehouse workforce.

- Enhanced Accuracy: The new solution increased overall accuracy in picking, leading to higher customer satisfaction and improved relationships with retail suppliers.

- Engaged Teams: Providing efficient tools empowered warehouse teams and increased engagement, contributing to a more productive work environment.

Partnering Approach

Tin Shack praised Logiks for their collaborative approach and commitment to understanding their business needs. As a true partner, Logiks demonstrated flexibility, accessibility, and effective communication throughout the project. They prioritized Tin Shack’s success and provided ongoing support to ensure a smooth transition and continued operational efficiency.

A Bright Future

By implementing Logiks’ Warehouse Management Suite, Tin Shack successfully optimized their warehouse operations, achieving significant improvements in efficiency, accuracy, and cost savings. The partnership with Logiks not only addressed immediate challenges but also provided a foundation for future growth and success.

Download as PDF